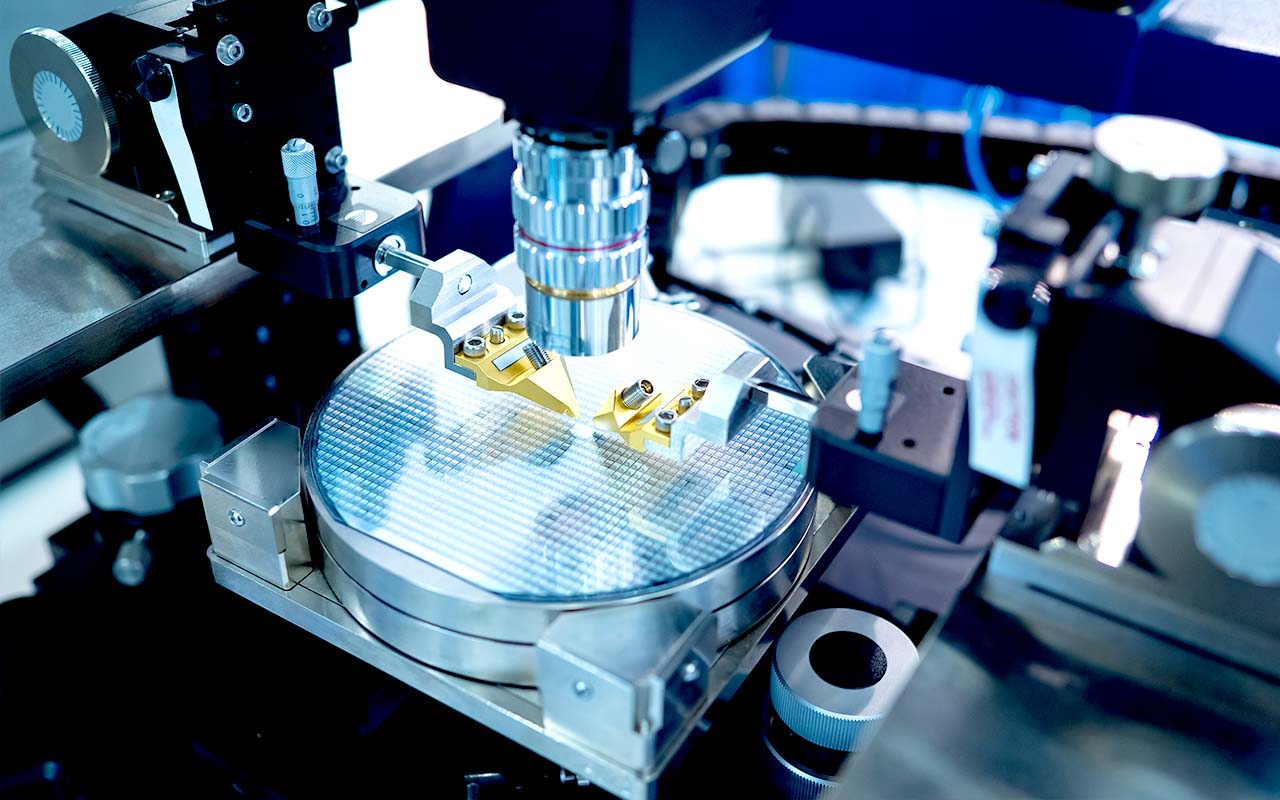

Wet etching processes in semiconductor manufacturing involve prolonged exposure to corrosive chemical baths, acids, and high-purity solvents. These harsh liquid environments present unique sealing challenges, requiring materials that offer excellent chemical resistance, purity, and mechanical stability. Katon® FFKM O-rings are specifically engineered for use in wet process tools, including chemical baths, cleaning systems, and wafer etch tanks. Our compounds are designed to resist swelling, leaching, and degradation in acidic and oxidizing media—helping ensure equipment uptime, yield protection, and process purity.