Articles

O-Ring Groove Design and Extrusion Causes | Prevent Sealing Issues in critical applications.

When O-rings fail in service, the problem is often blamed on the seal material. Many assume the O-ring has “melted” or that a poor-quality compound was supplied. In reality, the most common cause is not the material itself but groove design errors or incorrect O-ring sizing. Even the most advanced compounds, including FKM and FFKM, cannot perform reliably if the groove does not support them correctly.

Groove design is not just about providing space for an O-ring. It governs how the seal compresses, reacts to pressure, handles temperature changes, and tolerates chemical exposure. In short, the groove is as critical to sealing reliability as the O-ring itself.

Why Application Conditions Matter

Before defining groove geometry, engineers must understand what the O-ring will face in service. Pressure, motion, chemical media, and temperature all interact with the groove. A design that works in CAD may fail quickly if it doesn’t account for real-world conditions.

- Static vs. Dynamic: Static seals require consistent compression, while dynamic seals must balance compression with reduced friction and wear. High-speed or poorly lubricated applications demand especially careful design to minimize drag and heat buildup.

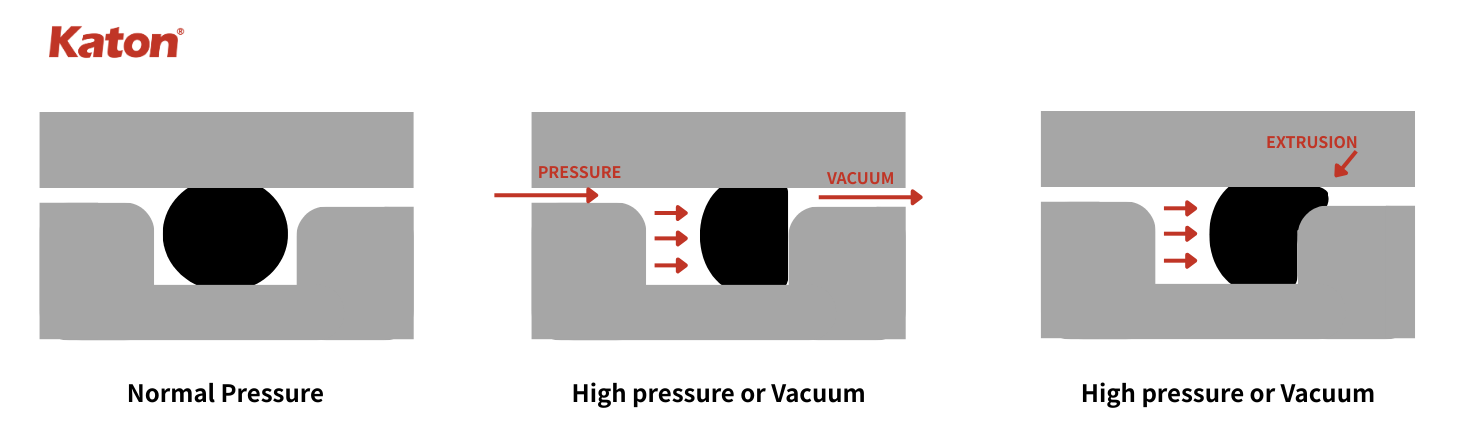

- Working Enviornment Pressure: High pressures or vacuum enviornments can force elastomers into extrusion gaps.

- Thermal Factors: while large temperature swings may alter compression levels through thermal expansion.

- Chemical Factors: Certain fluids can swell the O-ring, leading to overfilling and stress if no allowance is made in the groove.

- Material Behavior: FFKM and FKM provide excellent resistance to chemicals and heat, but like all elastomers, they expand and change dimension under load. Groove design must account for this natural behavior to maintain sealing integrity.

Core Groove Design Factors

Compression and Squeeze Margin |

The squeeze applied to an O-ring generates the sealing force. In dynamic applications, the squeeze margin must be minimized to reduce sliding resistance, wear, and compression set. In static designs, higher compression can be tolerated, though flange seals require additional margin to offset flange distortion and bolt stretch. Typical static compression falls in the 15–30% range, while dynamic designs call for lower values. |

Groove Fill |

Groove fill describes how much of the groove volume the O-ring occupies. The ideal range is around 65–85%. If the groove is overfilled, there is no room for thermal or chemical expansion, causing overstress or failure. If underfilled, the O-ring may not generate sufficient sealing force, leading to leakage. |

| Stretch and Interference | When an O-ring is installed over a shaft or into a bore, it must stretch or compress to stay seated. Too much stretch thins the cross-section, reducing contact pressure and increasing the risk of early failure. Balanced stretch or interference ensures the O-ring maintains sealing integrity without internal stress. |

| Gaps and Extrusion | At low pressures, the O-ring seals through elastic recovery. As pressure increases, the seal is pressed tighter against the groove walls. At very high pressures, the O-ring can extrude into clearance gaps, leading to nibbling or tearing. But extrusion isn’t caused by pressure alone. Assembly and installation practices often create the conditions for premature seal failure. The following are some of the common causes of extrusion

|

| Thermal Expansion and Swelling | Elastomers expand with heat and can swell in aggressive fluids. Without adequate clearance, expansion will force the O-ring against groove walls, creating excessive stresses and premature damage. Proper groove design leaves space for predictable volume growth. |

Heres how Pressure or Vacuum enviornments cause might cause o-ring extrusion:

Precision, Tolerances, and Assembly

Even when the groove is well-designed in theory, manufacturing tolerances and assembly practices can undermine performance. Machining at the high or low end of a tolerance range can shift squeeze margins, while rough surface finishes can abrade the O-ring or create micro-leakage paths. Assembly errors — from over-torqued fasteners to misalignment — also affect how the O-ring seats in the groove. A robust design anticipates these variables by including safety margins that tolerate real-world variation.

Designing for Reliability and Serviceability

A well-designed groove not only supports sealing performance but also makes installation and replacement straightforward. Sharp corners or inaccessible housings can damage seals during assembly and increase downtime during service. Small design details — such as adding corner radii or ensuring enough access space — extend seal life and simplify maintenance.

Validation testing is also essential. Verifying groove performance under actual pressure, temperature, and chemical conditions ensures long-term reliability and reduces the risk of unexpected field failures.

Best practices and solutions for extrusion:

-

Use backup rings in high-pressure service to block extrusion pathways.

-

Apply correct and even torque during assembly to prevent flange distortion.

-

Always use the proper O-ring installation tools not sharp metal objects.

-

In demanding dynamic environments, specify harder durometer or extrusion-resistant compounds.

Conclusion

Groove design is often overlooked until a seal fails. Yet many O-ring problems attributed to material defects are really the result of improper groove geometry or incorrect sizing. Compression ratios, groove fill, extrusion gaps, tolerances, and service conditions all play a role in sealing success.

With proper design, even the most challenging applications — from semiconductor plasma systems to oilfield drilling equipment — can benefit from reliable, long-lasting sealing performance.

Contact a Katon engineer today to discuss how optimized groove design can extend the life and reliability of your FKM and FFKM seals.