技術記事

FFKM架橋システム|架橋方式がFFKM Oリング性能に与える影響

(本記事は英語版からの翻訳です。)

FFKMの加硫システム:高性能シールを支える化学構造

FFKM(全フッ素エラストマー)シールは、極めて過酷な化学的・熱的条件下で使用されるアプリケーションにおいて不可欠な存在です。

ベースポリマーが性能の基盤を形成しますが、最終的にシール性能を左右するのは加硫システム(架橋反応の化学構造)です。

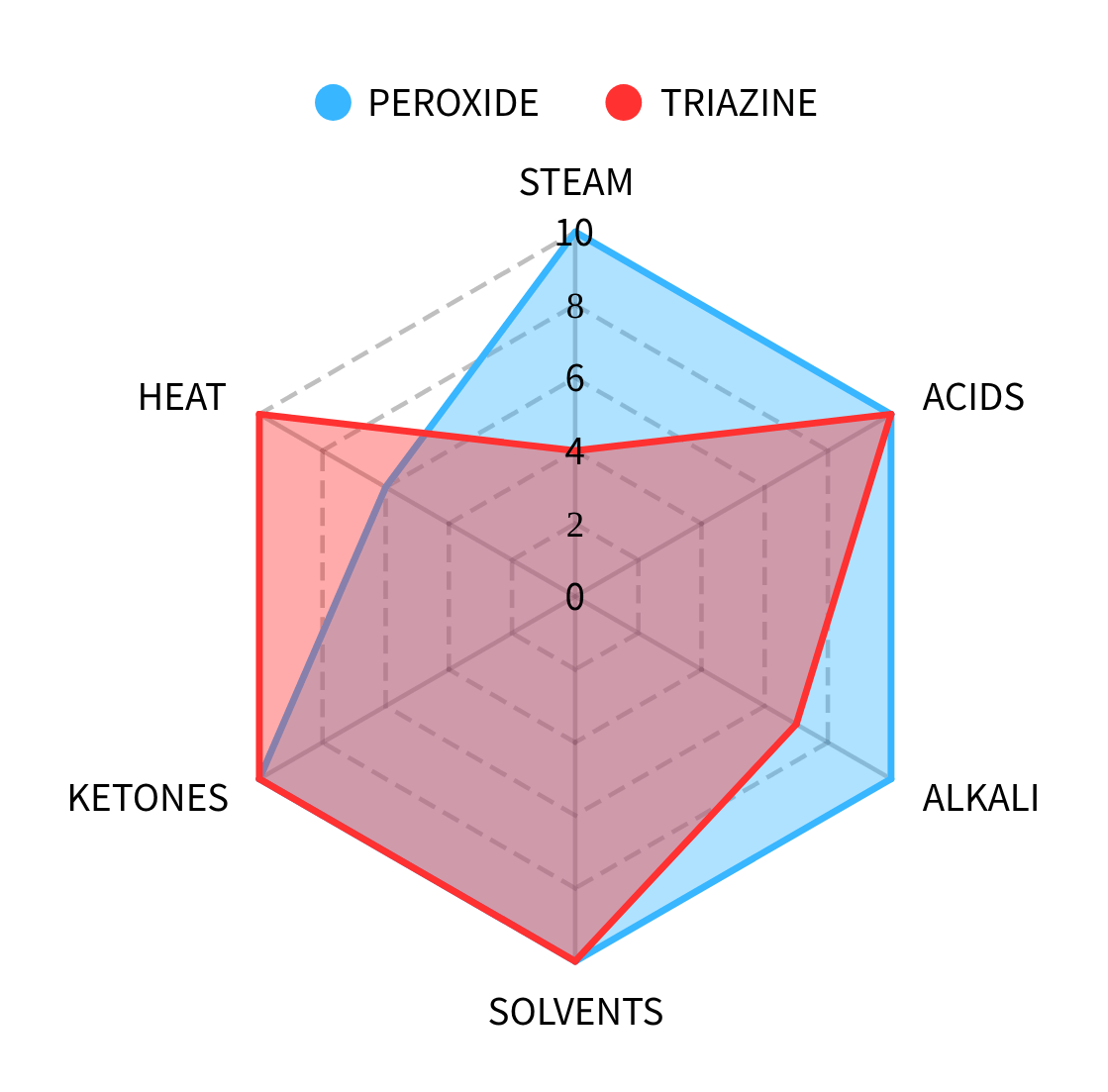

過酸化物(Peroxide)、トリアジン(Triazine)、ビスフェノール(Bisphenol)など、加硫方式の違いを理解することは、半導体製造、化学プラント、医薬装置、高温ガスシールなどの用途において、最適なFFKM材料を選定する上で極めて重要です。

Katon® Sealでは、これら3種類の加硫システムすべてを用いたFFKM化合物を開発し、世界中の顧客ニーズに対応しています。

過酸化物加硫:信頼性の高い万能タイプ

過酸化物加硫型FFKMは、最も広く使用されている加硫システムです。性能のバランスが取れており、酸・溶剤・蒸気・熱水など幅広い薬品に対応します。

動的および静的条件下でも優れたシール性能を維持し、約230°C(グレードによっては最大290°C)まで安定した性能を発揮します。

このタイプは、化学プラント、湿式半導体装置、反応槽、バルブなどの日常的なシーリング用途に最適です。

ただし、長時間の高温環境では弾性低下が生じる場合があるため、連続高温運転が必要なアプリケーションには他の加硫方式が推奨されます。

多用途かつコストパフォーマンスに優れた過酸化物加硫型FFKMは、多くのエンジニアや購買担当者にとって信頼できる選択肢です。

トリアジン加硫:高温安定性を追求した設計

高温環境下で優れた耐久性を求める場合、トリアジン加硫型FFKMが最適です。

このタイプは、320°C近い高温でも形状と弾性、シール力を長期間維持できるように設計されています。

一方で、加硫構造上の特性により、水分・蒸気・アミンなどに対しては過酸化物加硫型よりも劣化しやすい傾向があります。

そのため、湿潤環境での使用には適していませんが、乾燥高温環境(ドライヒートやプラズマ装置)では最も優れた性能を発揮します。

最近では、改良型のトリアジン加硫技術により、蒸気環境でも高い耐久性を発揮する新世代FFKMも登場しています。

ビスフェノール加硫:FKMで一般的、FFKMでは限定的

ビスフェノール加硫は、主にFKM(フッ素ゴム)で使用される方式で、イオン性の反応を利用して架橋構造を形成します。

特定の用途では有効ですが、高性能FFKMには適していません。

その理由は、過酸化物加硫やトリアジン加硫に比べて耐薬品性・耐熱安定性が劣るためです。

ビスフェノール加硫型のFFKMは、限定的な低要求アプリケーションでのみ使用されることが多く、半導体や航空宇宙など高信頼性分野ではほとんど採用されません。

Katon® Oリング:FFKMの専門知識と信頼性

Katon® では、アプリケーションごとに最適な加硫システムを採用したFFKM Oリング、ガスケット、カスタム形状部品を提供しています。既存の他社材料からの置き換えや、新規プロセス設計にも対応できるよう、性能データの透明性、技術コンサルティング、安定した生産体制を整えています。

FFKM材料の選定にお悩みですか?こちらからお問い合わせいただくか、製品ページでKatonの高性能シーリングソリューションをご覧ください。